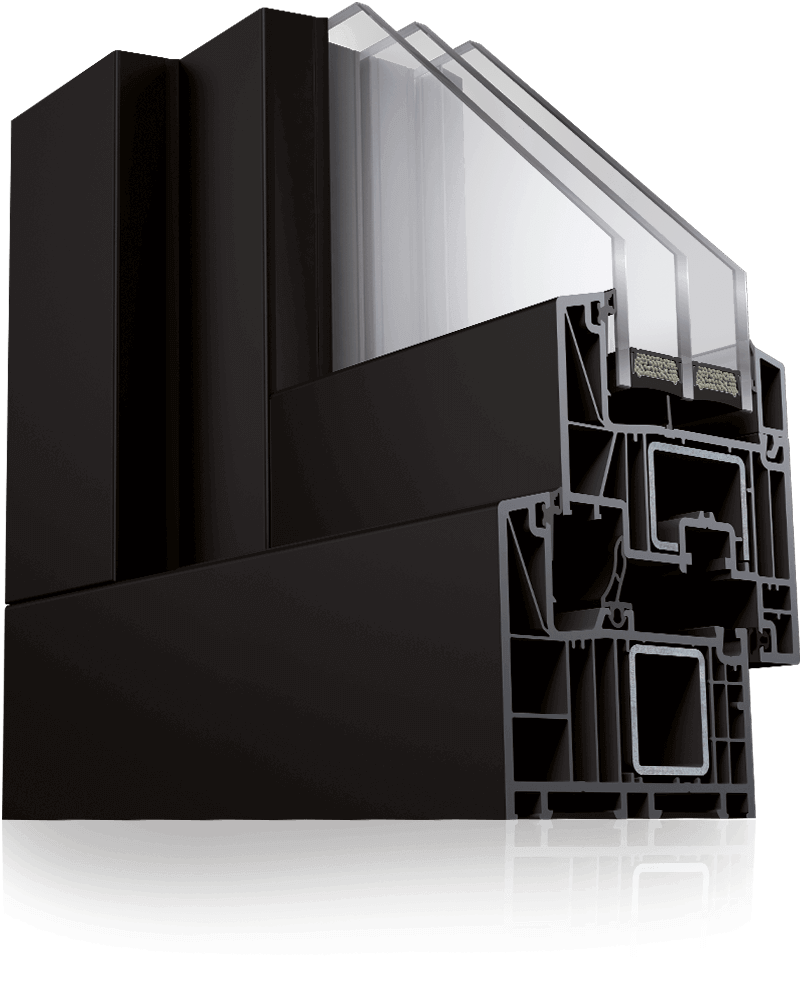

Plastic windows are made of polyvinyl chloride, a material with nearly one hundred fold less rigidity compared to steel. Therefore, PVC profiles use solutions to achieve the appropriate properties of the structure. Steel reinforcement is an element that allows the profiles to be properly stiff.

Rigidity of PVC profiles – why is it so important?

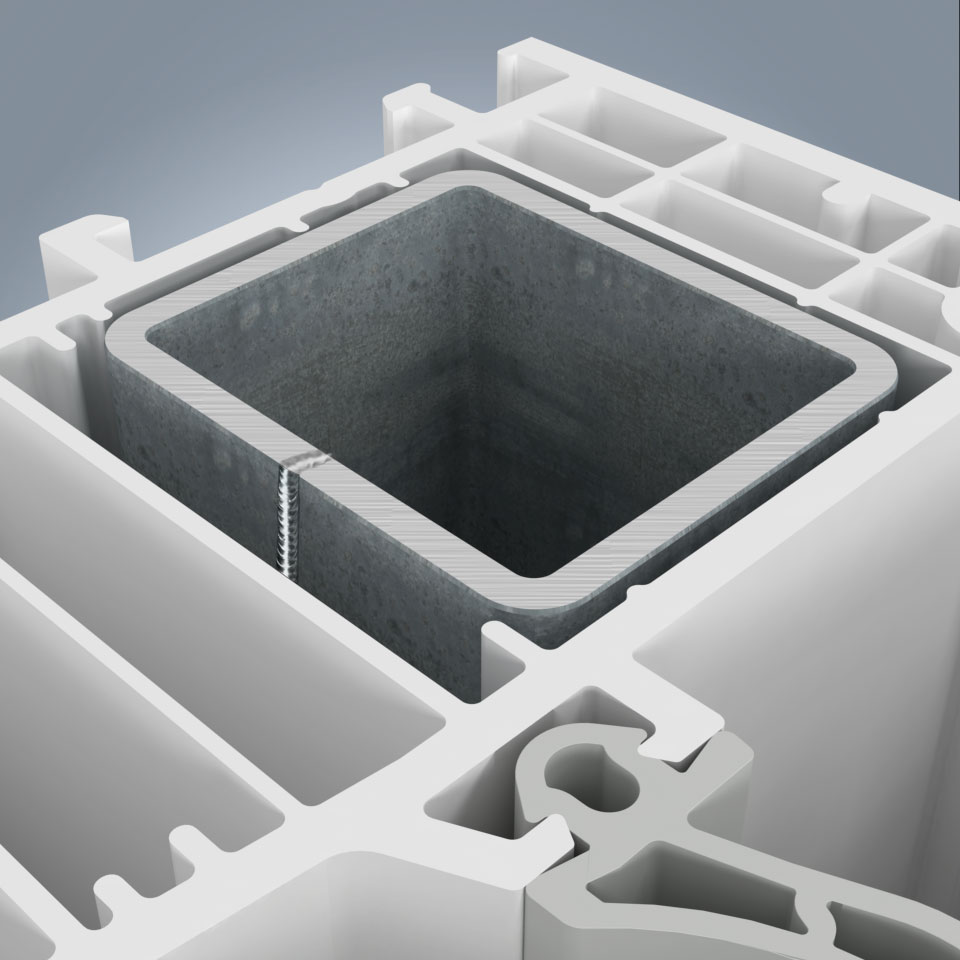

Proper rigidity of the profiles is necessary for the window to function properly. This element is employed by various forces, such as wind pressure, theself-weight of the window and the movements of the window and building structure. The influence of temperature and solar radiation – especially in the case of coloured windows – is also not insignificant. Therefore, the structure must be of sufficient rigidity. As a result, it will not bend under the influence of forces acting on it.

Temperature, wind, rain, sound, radiation

Room temperature and humidity

Own weight

Movements from the structure

Building-related movements

Profile stiffness and design capabilities

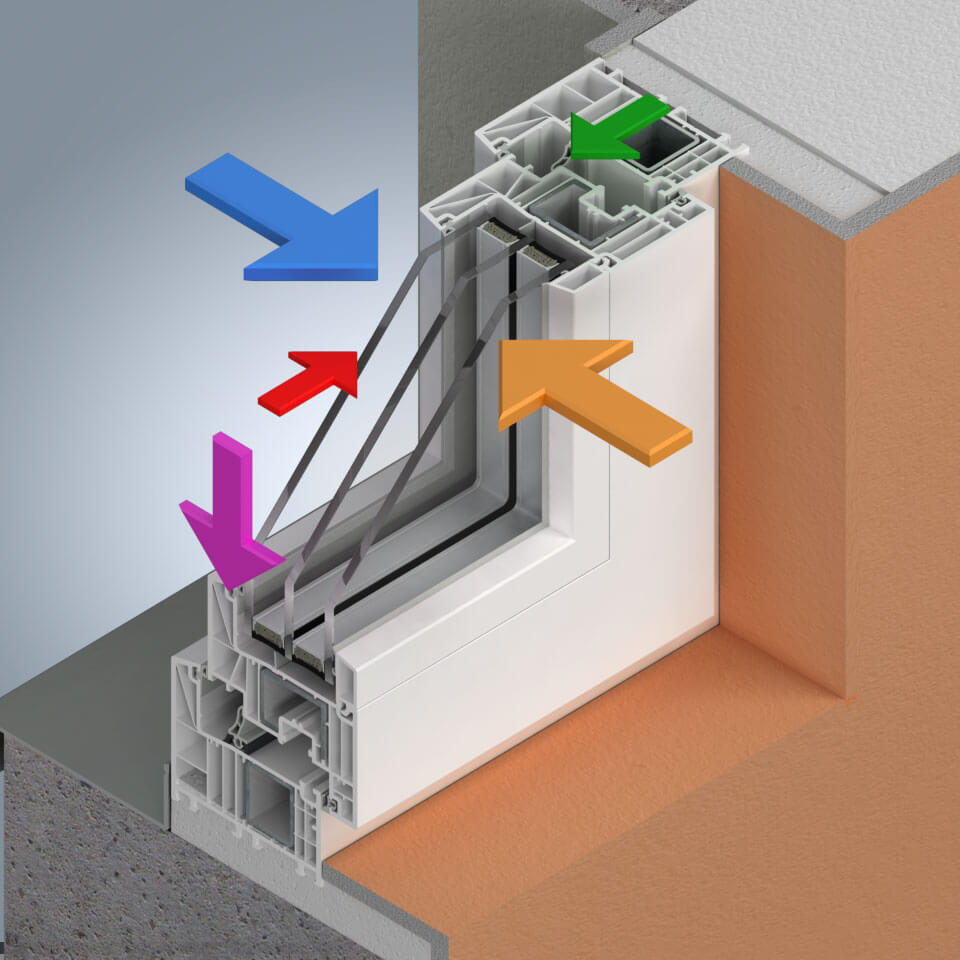

The rigidity of the steel profile in the window has a significant impact on the design possibilities. The larger it is, the larger the glazing elements can be performed from a given profile. Often the limitation is the size of the chamber in the profile intended for reinforcement. Therefore, wider profiles are used for the largest profiles so that greater reinforcement can be placed in them. In order to make optimal use of the chamber intended for re-reinforcing, its shape must be chosen accordingly. The thickness of the steel from which the reinforcement is made is also an important issue.

Steel reinforcement in MS products more than WINDOWS

Many profiles used for the production of windows in MS more than WINDOWS use closed steel reinforcement, laser welded. It is located in m.in. in multi-chamber profiles of the bluEvolution 82 series,used in the production of window frames in md version. In addition, the factory uses steel shapes with a thickness of 2.5 or 3 mm. In the group of solutions used there are also steel bars with a thickness of up to 10 mm.

Gain shape and strength

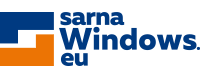

From a mechanical point of view, the most advantageous strength properties can be obtained when using a round tube. It is therefore the construction cranes that are made of such elements. Unfortunately, a circular pipe cannot be placed in the window profile. To ensure the best possible properties, a rectangular steel pipe is used in MS windows where this can be achieved. This shape allows you to make the most of the space inside the profile and ensure proper rigidity.

How is the steel reinforcement made closed?

A strip of sheet metal is bent to form a specific, closed shape. The free edges are welded with a laser. This preserves the correct shape. Importantly, the element not only does not bend, but also better copes with the transmission of the forces acting on it – especially those who try to twist the window frame. Therefore, setting the window in the wall accordingly becomes much easier. This ensures its proper functioning for a long time.

Effect of reinforcement on window parameters

The use of a closed steel reinforcement in the frame creates an additional, seventh chamber. This has a beneficial effect on the thermal insulation of the window. In addition, the closed high rigidity reinforcement provides improved safety. Due to the fact that two screws securing anti-burglary catches are always screwed to it, the structure is protected against burglary.